Company Address: Tiexi Industrial Park, Haicheng City, Liaoning Province

Contact person: Manager Zhang

Contact :13112347171

mailbox:lnthjc@126.com

Company website:en.lnthjc.com

Patent Name of Aluminum Alloy Automobile Castings: Manufacturing Method of Bolted Connection Structure to Prevent Galvanic Corrosion of Aluminum Alloy

In the technical field:

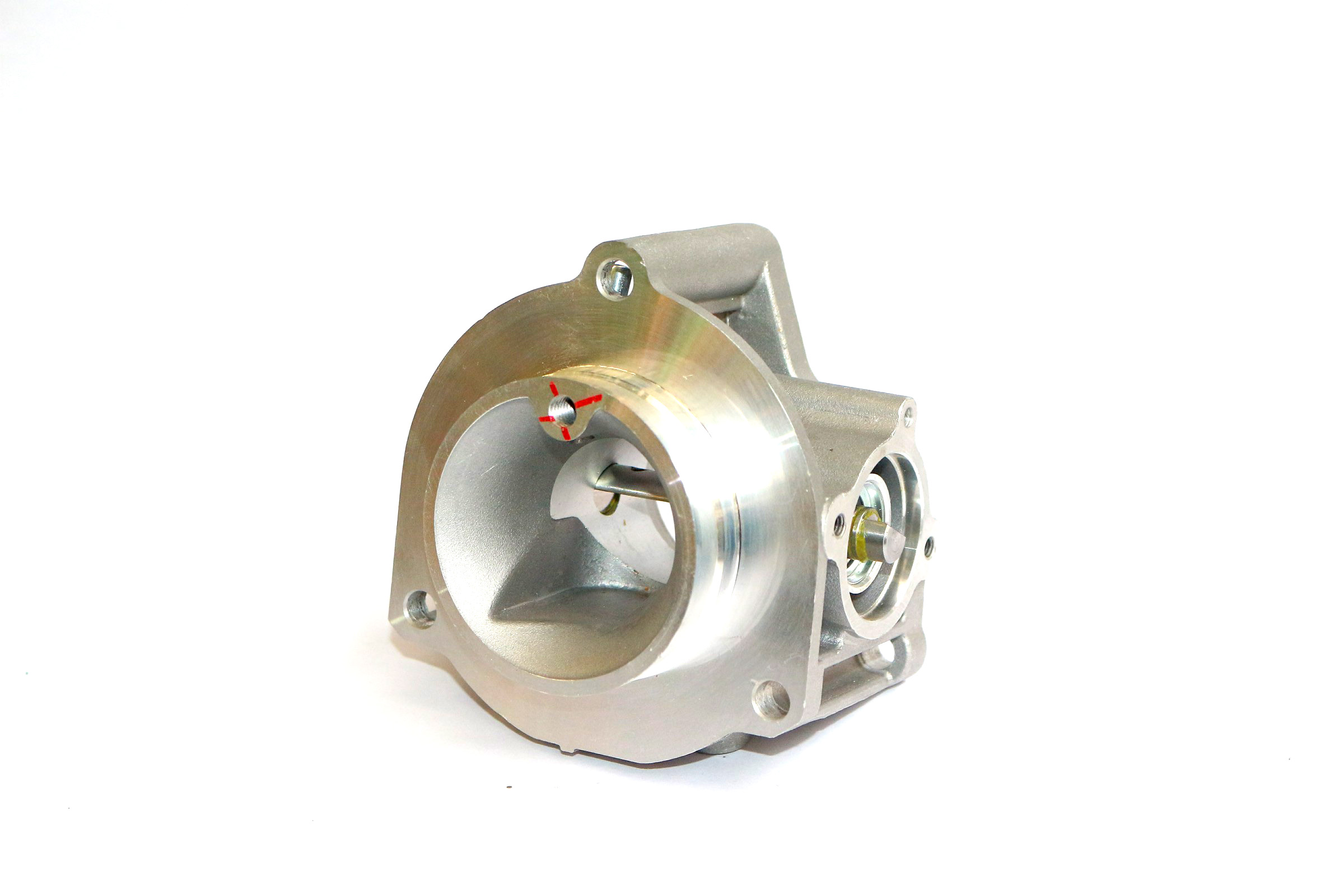

The utility model relates to a bolt connection structure of a mud seed, in particular to a bolt connection structure for preventing galvanic corrosion of aluminium alloy, belonging to the technical field of fasteners.

Background technology:

The application of aluminium alloy in automobiles is gradually increasing. Bolt connection structure may be used in connection. In order to ensure the connection strength, steel bolts must be selected. Because the electrode potential of steel is higher than that of aluminium alloy, galvanic corrosion will occur in the case of corrosive medium. That is to say, the contact of two metals with different electrode potential of aluminium alloy parts and steel bolts in corrosive medium will cause galvanic corrosion. The electrochemical corrosion makes the aluminium alloy corrode or even crack at the bolt hole, which seriously affects the quality and safety of automobiles. For example, China Utility Model Patent Notice No. 20146 1703U,

Open Day, May 12, 2010. The utility model patented open mud seed tightening device for preventing thread tightening contact corrosion includes bolts or studs, nuts, lower isolation sleeve, upper isolation sleeve and isolation pad. The small ends of lower isolation sleeve and upper isolation sleeve are loaded into the connecting holes of the connected magnesium alloy parts and other alloy parts to form a dynamic mating connection, and the isolation pad is placed in the connecting holes of the connected magnesium alloy parts. A contact connection is made between the magnesium alloy parts and other alloy parts, and the inner holes of the upper isolation sleeve, the connecting holes of the isolation pad and the lower isolation sleeve of the connecting holes of the other alloy parts are aligned. The nuts are screwed tightly on the bolts through the inner holes of the lower isolation sleeve and the upper isolation sleeve to form a fixed connection. However, the isolation sleeve used in the device has complex structure, high manufacturing cost and is not easy to install and replace.

The purpose of the utility model is to provide a bolt connection structure with simple structure, convenient installation, easy maintenance and replacement, which can effectively prevent the galvanic corrosion of aluminum alloy at the bolt hole and prevent the galvanic corrosion of aluminum alloy. To achieve the above purpose, the technical solution of the utility model is a bolt connection structure to prevent galvanic corrosion of aluminium alloy, including a bolt rod, one end of which is a bolt head, and the other end of the bolt rod is provided with an external thread. The bolt rod passes through the installation holes on the upper plate of aluminium alloy and the lower plate of aluminium alloy, and is fixed by a nut, and the joint between the bolt head and the upper plate of aluminium alloy is fixed by a nut. A bearing upper gasket is arranged at the position, and a bearing lower gasket is arranged at the joint part between the nut and the aluminum alloy lower plate. The ring coat of the bearing upper gasket is provided with an anodic corrosion upper gasket, and the ring coat of the bearing lower gasket is provided with an anodic corrosion lower gasket. The inner hole diameter of the gasket on the anodic corrosion is smaller than the diameter of the bolt head and larger than the diameter of the bolt rod. The inner hole diameter of the gasket under anodic corrosion is smaller than the diameter of the nut and larger than the diameter of the bolt rod. The thickness of the gasket on the anodic corrosion is O. Imm-O. 5 mm higher than that of the gasket on the bearing force, and the thickness of the gasket on the anodic corrosion is O. Imm-O. 5 mm higher than that of the gasket on the bearing force. The utility model has the beneficial effect that I. On the basis of the existing aluminium alloy bolt connection structure, the upper and lower bearing gaskets and the upper and lower anodic corrosion gaskets are added to the utility model, and the two different electrode potential metals of aluminium alloy parts and steel bolts are separated, thus effectively preventing the galvanic corrosion of aluminium alloy at the bolt hole. [0011]2. The utility model has the advantages of simple structure, convenient installation and replacement. By isolating the upper and lower anode corrosion gaskets from the bolts, the galvanic corrosion of the aluminum alloy is prevented, the service life is prolonged, and the fastening effect is good.

Liaoning Tianhai Tiancheng Equipment Manufacturing Co., Ltd. Copyright Ownership Yingkou Zhongchuang Network Technology Co., Ltd. Provides technical support