Company Address: Tiexi Industrial Park, Haicheng City, Liaoning Province

Contact person: Manager Zhang

Contact :13112347171

mailbox:lnthjc@126.com

Company website:en.lnthjc.com

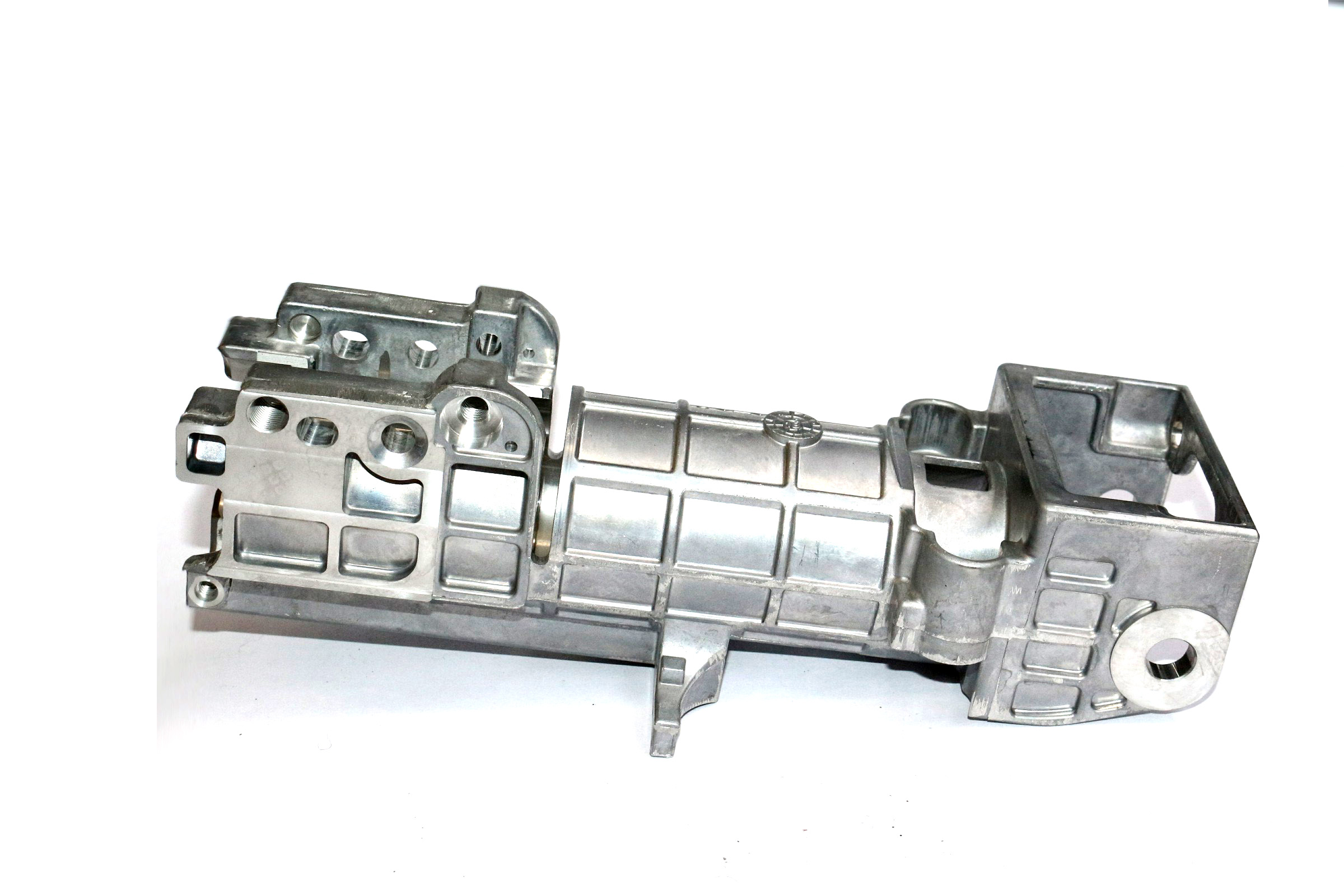

Manufacturing Method of Aluminum Alloy Casting Integral Aluminum Alloy Car Shell

[Technical field]

The utility model relates to an electric motor accessory, in particular to a vehicle chassis.

[Background technology]

With the development of explosion-proof motor, the technology of water-cooled shell has been improved continuously. In the existing technology, a casting method of water-cooled motor shell has been disclosed in the Chinese invention patent No. CN201410438179.9. The shell is made of cast aluminium alloy and has a shell and a base. The shell is equipped with a strip spiral water channel, a strip spiral water channel and a shell which are integrated with the shell. Integrated casting.

At present, the main development direction of the processing technology of water-cooled vehicle chassis is holistic and aluminized. However, in the current structure of vehicle chassis, the water pipe interface is directly used as the sand drain hole after casting. However, due to the low surface strength of aluminium alloy, it is easy to wear the water pipe interface during the sand drainage process, which affects the sealing of the water pipe interface and causes the car chassis to be in the process of sand drainage. In the later use process, water leakage and other defects are easy to occur.

[Contents of utility models]

In view of the shortcomings of the existing technology, the purpose of the utility model is to provide an integral alloy motor housing with simple processing technology and good sealing performance.

To achieve the above purpose, the utility model provides the following technical scheme: an integral aluminium alloy vehicle housing, including a cylindrical shell body, a number of annular cooling channels are arranged on the inner wall of the shell body, a water pipe joint is arranged on the outer side of the shell body, and the cooling water pipe joint is connected with the water pipe joint. Among them, a number of sand drains are arranged on the shell body. The sand discharge hole is connected with the cooling water channel.

By adopting the above technical scheme, the sand mould in the casting process is discharged by adding sand discharge holes, which can effectively avoid the damage of the sand mould to the water pipe joint, and the sand discharge holes are no longer limited to the diameter of the water pipe, and can be increased to a certain extent, so as to facilitate sand discharge and improve the efficiency of sand cleaning. After sand discharge, the sand discharge holes can be sealed.

Manufacturing Method of Aluminum Alloy Casting Integral Aluminum Alloy Car Shell

[Technical field]

The utility model relates to an electric motor accessory, in particular to a vehicle chassis.

[Background technology]

With the development of explosion-proof motor, the technology of water-cooled shell has been improved continuously. In the existing technology, a casting method of water-cooled motor shell has been disclosed in the Chinese invention patent No. CN201410438179.9. The shell is made of cast aluminium alloy and has a shell and a base. The shell is equipped with a strip spiral water channel, a strip spiral water channel and a shell which are integrated with the shell. Integrated casting.

At present, the main development direction of the processing technology of water-cooled vehicle chassis is holistic and aluminized. However, in the current structure of vehicle chassis, the water pipe interface is directly used as the sand drain hole after casting. However, due to the low surface strength of aluminium alloy, it is easy to wear the water pipe interface during the sand drainage process, which affects the sealing of the water pipe interface and causes the car chassis to be in the process of sand drainage. In the later use process, water leakage and other defects are easy to occur.

[Contents of utility models]

In view of the shortcomings of the existing technology, the purpose of the utility model is to provide an integral alloy motor housing with simple processing technology and good sealing performance.

To achieve the above purpose, the utility model provides the following technical scheme: an integral aluminium alloy vehicle housing, including a cylindrical shell body, a number of annular cooling channels are arranged on the inner wall of the shell body, a water pipe joint is arranged on the outer side of the shell body, and the cooling water pipe joint is connected with the water pipe joint. Among them, a number of sand drains are arranged on the shell body. The sand discharge hole is connected with the cooling water channel.

By adopting the above technical scheme, the sand mould in the casting process is discharged by adding sand discharge holes, which can effectively avoid the damage of the sand mould to the water pipe joint, and the sand discharge holes are no longer limited to the diameter of the water pipe, and can be increased to a certain extent, so as to facilitate sand discharge and improve the efficiency of sand cleaning. After sand discharge, the sand discharge holes can be sealed.

Liaoning Tianhai Tiancheng Equipment Manufacturing Co., Ltd. Copyright Ownership Yingkou Zhongchuang Network Technology Co., Ltd. Provides technical support